Mashiinka Milling VMC850B CNC, xarunta mashiinka toosan

Tilmaamaha Alaabta

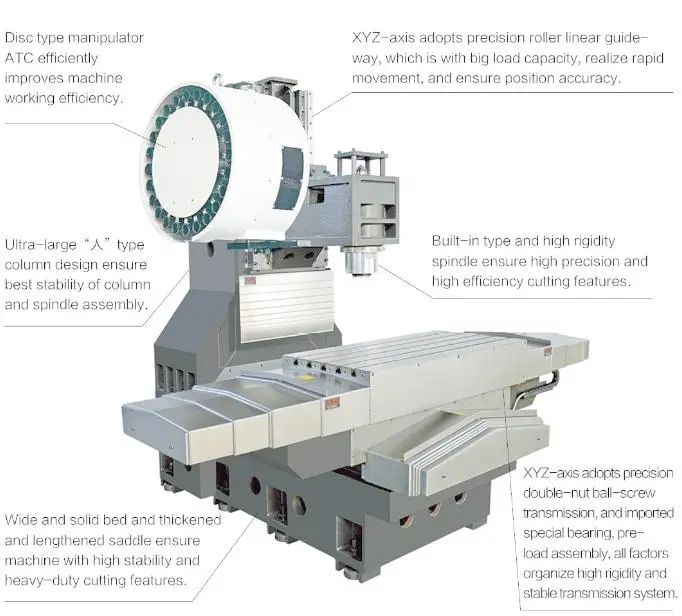

1.Guud ahaan tilmaamaha

Mashiinkan waxaa loo qaabeeyey qaab qaabaysan. Tiirku waxa uu ku dul dul saaran yahay jidhka mishiinka, sanduuqa dunta dunta waxa uu ku dul dul wareegayaa tiirka samaynaysa dhaqdhaqaaqa dhidibka Z, duleelyada kooraha ee mishiinka jidhka samaynaaya dhaqdhaqaaqa dhidibka Y. Saddex faasas waa dhammaan hagitaan toosan oo leh xawaarihii quudinta sare iyo saxnaanta sare. Waxaan u isticmaalnaa birta cawl tayo sare leh oo loogu talagalay jirka mashiinka, tiirka, koorasaha, miiska shaqada, sanduuqa dunta leh ee tignoolajiyada ciidda resin iyo 2 jeer daawaynta gabowga si loo baabi'iyo walwalka haraaga gudaha ee walxaha. Qaybahaan dhamaantood waxaa hagaajiyay software-ka SolidWorks, kaas oo wanaajinaya adkeysiga iyo xasiloonida kaliya maahan qaybahan laakiin mashiinka. Sidoo kale waxay xajin doontaa qallafsanaanta iyo gariirka ay sababto goynta. Qaybaha muhiimka ah ayaa dhamaantood laga soo dhoofiyaa astaanta caanka ah ee adduunka si ay mashiinka u sameeyaan xasillooni iyo adkeysi sare. Mashiinkan waxa uu gaadhi karaa habka wax-shiididda, qodista, reaming, caajiska, reaming, tuubada iyo sida caadiga ah loo isticmaalo Military, macdanta, baabuurta, caaryada, qalabaynta iyo warshadaha kale ee farsamada. Waxaa loo isticmaali karaa dhammaan noocyada kala duwan ee saxnaanta sare iyo moodooyinka habka badan. Waxay u fiican tahay kuwa yaryar iyo kuwa dhexdhexaadka ah, wax soo saarka kala duwan, sidoo kale waxay gelin kartaa khadka wax soo saarka si toos ah.

2.Saddex faasas

Saddex faasas waa dhammaan hagitaan toosan oo leh nashqad baaxad weyn oo sax ah oo waara. Matoorada 3 faasas waxa ay si toos ah ugu xidhan yihiin kubad sax ah oo saraysa iyada oo aan lahayn wax farqi ah isku xidhid dabacsan. Kubbad kasta oo 3 faashad ah ayaa laga soo dhoofiyaa kubbadda kubbadda xaglaha saxda ah ee lala xiriiriyay iyo xirmooyin xirfad leh oo la mid ah, sidoo kale waxaan sameyn doonaa xiisadda hore ee kubbadaha kubbadda si sax ah iyo saxsanaan sare oo sax ah. Haddii ay dhacdo koronto la'aan, bareegga mootada waxaa si toos ah u hayn kara biriiga si looga hortago inuu wareego, kaas oo door ka ciyaara ilaalinta badbaadada.

3.Cuub lafdhabarta

Spindle-ka waxaa soo saaray soo-saare xirfad leh si loo hubiyo saxnaanta sare iyo adkaanta. Spindle-qaadashada waxay ka timid astaanta saxda ah ee caanka ah ee caanka ah adduunka, waxayna ku soo ururtay xaalad heerkul joogto ah oo aan boodh lahayn. Taas ka dib , oo dhan dunnidu waxay samayn doonaan imtixaanka dheelitirka firfircoon si loo hubiyo in taako nolosha iyo trust.It waxaa ku qalabaysan cadaadis hoose nidaamka ilaalinta wareegga hawada, afuufi hawada cadaadis hoose galay dhexda meel bannaan oo gudaha samaynta lakabka ilaalinta hawada si looga hortago boodhka, qaboojiyaha galay. dunta dunta. Xaaladdan, xajinta dunta waxay ka hoos shaqayn doontaa jawi wasakhaysan, kaas oo ilaalin doona unugga dunta iyo cimri dhererka dunta dunta. Xawaaraha Spindle-ku ma noqon karo wax-tallaabo ah oo laga beddelo xadka xawaaraha Spindle-ka, kaas oo ay maamusho koodhka gudaha ee matoorka si uu ula socdo jihaynta dunta dunta iyo taabashada adag.

4.Qaabka beddelka nidaamka

Awoodda joornaalka qalabka caadiga ah ee mashiinkani waa 24T waxaana lagu soo ururiyay tiirka dhinaca. Marka ay bedesho qalab, saxan saxan wadista iyo in la meeleeyo by motor drive hobbing camera farsamaynta, ka dib markii dunidu soo gaadho booska beddelka qalab, ATC gaadhi doonaa beddelka qalab iyo diri tallaabo qalab. ATC waxa ay hobbing farsamaynta kamarada oo ay ka dhigaysaa xiisad ka hor markaas awood u leh wareeg ah xawaare sare, taas oo u fiican in si degdeg ah oo sax ah qalab beddelo.

5.Nidaamka qaboojinta

Mashiinku wuxuu ku qalabaysan yahay bamka qaboojinta qulqulka qumman ee qulqulaya iyo haanta biyaha ee awoodda weyn. Xawaaraha bamka qaboojinta waa 2m³/saacaddii si loo hubiyo in dib-u-warshadayn ku filan Waxaa jira biibiile qaboojin oo ku yaal dusha sare ee sanduuqa dunta dunta, kaas oo ka dhigi kara qaboojiye hawo iyo qaboojiye biyaha qalabka iyo qaybaha shaqada. Ku qalabaysan qoriga hawada si loo nadiifiyo mishiinka iyo qaybaha shaqada.

6.Nidaamka sambabada

Qaybta pneumatic waxay sifeyn kartaa wasakhda iyo qoyaanka isha gaaska si looga fogaado burburka iyo nabaad-guurka qaybaha mashiinka. Qaybta Solenoid valve waxay maamusho barnaamijka PLC si ay u hubiso in ficilada qalabka dunta dunta dunta, xarunta dunta dunta, qalabka xadhigga dunta iyo qaboojiyaha dunta dunta loo samayn karo si degdeg ah oo sax ah. Mar kasta oo qalab beddela dunnidu, hawo cad oo cadaadis leh ayaa ka soo afuufi doonta xarunta dunidu si ay u nadiifiso godka dunta dhexdisa ee dunta iyo galka qalabka si ay u adag tahay isku darka dunta iyo qalabka. Waxay balaadhi doontaa dhererka nolosha dunta dunta.

7.Mashiinka ilaalinta

Waxaan u isticmaalnaa gaashaanka badbaadada caadiga ah mashiinka, kaas oo aan ilaalin karin oo kaliya qulqulka qaboojiyaha laakiin hawlgalka badbaadada. Jid kasta oo hagaya waxa ay ku qalabaysan tahay gaashaanka ilaalinta si ay uga hortagto qaboojiyaha iyo goynta qaybta gudaha oo hoos u dhigto xidhashada iyo nabaad guurka hagaha iyo biraha kubbadda.

8.Nidaamka sifaynta

Dariiqa hagaha iyo biraha kubbadda waxaa lagu qalabeeyay nidaamka sifaynta dhexe iyo kala-soocida saliidda mugga leh ee nood kasta, kaas oo ku siin kara saliid xaddi go'an iyo waqtiyo si loo hubiyo in weji kasta oo silid ah uu saliiday iyo hoos u dhigista. Waxa ay wanaajin doontaa saxnaanta iyo cimriga dheer ee kubad wareegta iyo hagida.

9.Nidaamka gudbinta Chip

Waxaan bixinaa qalabka gacanta gacanta caadiga ah ka saara chip-ka oo leh hawl fudud. Waxa kale oo aad dooran kartaa nooca fur-gudbinta ama nooca hinge-ga.

| Shayga | Unug | VMC640L | VMC640LH | VMC850L | VMC1000L |

| Miiska shaqada | |||||

| Cabbirka shaqada | mm | 400×900 | 400×900 | 500×1000 | 500×1200 |

| T-slot (N×W×D) | mm | 3×18×100 | 3×18×100 | 5×18×100 | 5×18×100 |

| Safarka | |||||

| dhidibka X safarka | mm | 640 | 640 | 850 | 1000 |

| Y dhidibka safarka | mm | 400 | 400 | 500 | 500 |

| dhidibka Z safarka | mm | 400 | 500 | 600 | 600 |

| Kala duwanaanshaha mashiinka | |||||

| Fogaanta xarunta dunta ilaa tiirka hore | mm | 440 | 476 | 572 | 572 |

| Fogaanta cidhifka dunta ilaa miiska shaqada | mm | 120-520 | 120-620 | 120-720 | 120-720 |

| cabbirka mashiinka | |||||

| L×W×H | mm | 2200×2100×2500 | 2200×2100×2550 | 2540×2320×2780 | 3080×2320×2780 |

| Miisaanka mashiinka | |||||

| Max. culeyska culeyska ee miiska shaqada | kg | 350 | 350 | 500 | 600 |

| Miisaanka mashiinka | kg | 3900 | 4100 | 5200 | 5600 |

| Spinal | |||||

| Spindle dalool taper | BT40 | BT40 | BT40 | BT40 | |

| Spinal power | kw | 5.5 | 5.5 | 7.5/11 | 7.5/11 |

| Max. xawaaraha dunta | rpm | 8000/10000 | 8000/10000 | 8000/10000 | 8000/10000 |

| Quudinta (wadi toos ah) | |||||

| Max. xawaaraha quudinta | mm/min | 10000 | 12000 | 12000 | 12000 |

| Xawaaraha quudinta degdega ah (X/Y/Z) | m/min | 20/20/10 | 30/30/24 | 32/32/30 | 32/32/30 |

| Kaashashka kubbadda (dhexroor + rasaas) | |||||

| Kubbada dhidibka X | 3210 | 3212 | 4016 | 4016 | |

| Kubbada dhidibka Y | 3210 | 3212 | 4016 | 4016 | |

| Kubbada dhidibka Z | 3210 | 4012 | 4016 | 4016 | |

| Tool Magazine | |||||

| Awoodda majaladda qalabka | T | 16 | 16 | 24 | 24 |

| Qalabka beddelka wakhtiga | s | 2.5 | 2.5 | 2.5 | 2.5 |

| Saxnaanta meelaynta (Heerka Qaranka) | |||||

| Saxnaanta meelaynta (X/Y/Z) | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| Saxnaanta dib-u-dhigista (X/Y/Z) | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| MAYA | Magaca | Summada |

| 1 | nidaamka CNC | Nidaamka Seimens 808D |

| 2 | Matoorka ugu muhiimsan | Qalabka Siemens oo buuxa oo ay ku jiraan servo motor |

| 3 | dhidibka X/Y/Z, darawalka | Seimens |

| 4 | Ballscrew | Hiwin ama PMI (Taiwan) |

| 5 | Qaadista kubbadda | NSK (Japan) |

| 6 | Tilmaamayaal toosan | Hiwin ama PMI (Taiwan) |

| 7 | Spindle motor | POSA/ROYAL (Taiwan) |

| 8 | Kulaylka beddelka | Taipin/Tongfei (Is-kaashatada) |

| 9 | Habka saliidaynta qaybaha ugu muhiimsan | Proton (Shirkadda Wadajirka ah) |

| 10 | Nidaamka pneumatic qaybaha ugu muhiimsan | AirTAC (Taiwan) |

| 11 | Qaybaha ugu muhiimsan ee nidaamka korontada | Schneider (France) |

| 12 | Bamka biyaha | Shiinaha |